Our expansive network is equipped for high volume and fast turnaround

HADID has an expansive network of powder coating facilities. Our state-of-the-art, highly automated operations are equipped for high-volume production with a turnaround time of as little as 24 hours for all of the industries we serve.

With HADID’s commitment to quality, we can meet and exceed the standards of a wide range of industries. These include, but are not limited to, aerospace, automotive, architectural, telecommunications, as well as oil & gas.

The best choice for decorative and functional finishes in powder coating

Our ISO 9001-certified process and our constant, never-ending focus on zero defects ensure a durable, attractive, long-lasting finish.

We have earned the following certifications:

- AS9100 (Aerospace Quality Management)

- Caterpillar (Heavy Equipment)

- General Dynamics (Aerospace and Defense)

- ISO (Quality Management)

- NADCAP Quality (Aerospace and Defense)

- PACCAR (Automotive)

Our facilities can handle items of any size, from small parts up to items 30 ft. in length

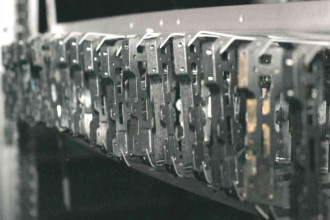

Our facilities utilize numerous conveyor lines, augmented by multiple batch lines to accommodate the powder coating of stampings, castings, extrusions, tubing, and many other products. Every part goes through a 3- or 5-stage iron phosphate washer and, when necessary, is cleaned by hand.

Related Featured Story

Related Case Study

Explore Related Powder Coating

Wet Coating

Uniform paint coverage, precision application, and corrosion protectionHadid high-quality wet coating operations have established us as a leading provider of protective finishes, including chemical agent-resistant coatings (CARC) for military equipment. Our expansive capacity enables us to finish parts up to 40 feet in length and include high-spec, intricate parts and masking.Wet coating is an effective method of applying a protective coating of liquid paint evenly to a wide range of materials, ...

Explore

Mil-Spec

Protection from radioactive, chemical, and biological agentsHADID is a leading provider of chemical agent-resistant coatings (CARC) meeting military specifications (Mil-Spec) established by the U.S. government. Our high-volume production capacity enables us to meet the fast turnaround times often required by the defense industry, and our capabilities include large format and heavy equipment parts.

Explore

Plating

Durable protection, high-spec capabilities, and operational agilityHADID's highly automated plating operations have high-volume production capacity and provide fast turnaround times, enabling us to integrate seamlessly into your supply chain. Our state-of-the-art technologies provide durable corrosion protection for substrates and components of varying sizes and high-spec, intricate designs. HADID Plating ProcessesAnodizingZinc PlatingNickel PlatingEmbrittlementElectroless Nickel (High and ...

Explore

Surface preparation

The key to ensuring a quality, consistent finishSurface preparation is critical to obtaining a high-quality finish, whether it be powder or wet coating. HADID has extensive expertise in sandblasting, which efficiently and effectively smooths rough edges and repairs surface blemishes. Our sandblasting capabilities extend to parts as large as 40 feet in length, and our quality control measures, by our ISO 9001 certification, ensure an optimal surface for comprehensive and consistent coating.Assuri...

Explore

E-Coating

Exceptional corrosion resistance with 100% coverageHADID's highly automated e-coating operations are equipped for high-volume production and fast turnaround times, which result in improved supply chain efficiency. E-coating provides comprehensive corrosion protection, enabling paint coverage to reach areas inaccessible by spray applications. A corrosion-resistant epoxy coating is created by applying an electrical current to a paint bath. The submerged part is energized to attract paint part...

Explore